History of Manufactured Gas Plants (MGPs)

Yesterday’s Energy Source

Supplies of clean, safe, reliable and affordable natural gas were not always available in Illinois. In fact, beginning in the mid-1800s, it was necessary to manufacture gas using processes developed in England. Manufactured gas plants (MGPs) provided gas for cooking, heating, lighting and, later, industrial applications. Cleaner and safer than wood or oil, manufactured gas dramatically improved people’s lives. As the demand for energy grew at the turn of the century, thousands of manufactured gas plants operated throughout the country. Towns that had a MGP were considered to be progressive and forward thinking.

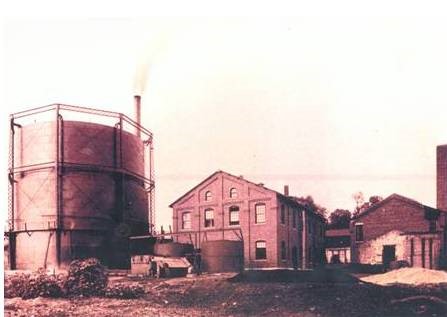

Typical Manufactured Gas Plant

Manufactured gas was produced when some combination of coal, coke and/or oil was heated to generate gas. The gas was cleaned of impurities and stored on site before it was delivered to the surrounding community.

In the 1920s and 1930s, the construction of natural gas pipelines across the country made a more affordable, cleaner energy choice available – natural gas. Manufactured gas ceased to be a major energy source in Illinois during the 1930s and the MGPs began to shut down.

Today’s Environmental Challenge

Manufactured gas production created byproducts such as ashes, cinders and tar. Tar was typically stored in underground structures at plant sites and sold for use in road paving, roofing materials and other commercial products. The environmental effects of tar and other plant residuals were not a concern at the time; however, today, we know more about tar and other residuals and are committed to managing byproducts from past operations in accordance with today’s safety and environmental standards.

MGP residuals can contain polycyclic aromatic hydrocarbons (PAHs), such as naphthalene; volatile organic compounds (VOCs), such as benzene and toluene; and metals and other inorganic materials. PAHs are commonly found in the environment because they form as a result of combustion, such as vehicle exhaust. VOCs are often found in fuels and solvents. Some of the MGP residuals can have odors similar to roofing tar or mothballs. Those odors occur at levels well below those that would present a health risk.

What Are We Doing About These Sites?

Nicor Gas is proactively addressing environmental issues related to MGP sites to bring these sites in line with current safety and environmental standards. Nicor Gas is in the process of investigating and remediating the sites, including the former Bloomington MGP. The project is being conducted in cooperation with, and oversight by, the Illinois EPA through its voluntary Site Remediation Program (SRP). Click here for more information about the SRP. The SRP establishes investigation and cleanup guidelines for sites using risk-based, site-specific cleanup objectives designed to be protective of people and the environment. Through the SRP, the Illinois EPA reviews and approves the cleanup work.

Successful participation in the SRP results in regulatory closure at the MGP site, primarily through the issuance of a No Further Remediation Letter by the Illinois EPA. The letter is filed with the county office that maintains property transfer records so that future landowners and others are aware that the site was previously cleaned up.